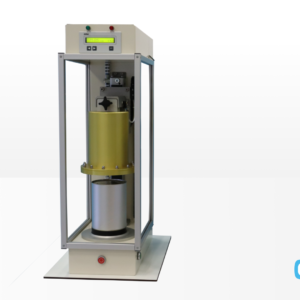

STATIONARY LEAK TESTER PHARMACEUTICAL (SLTP) – OXIPACK

Features:

- Non-destructive vacuum decay method (ASTM F2338)

- 21 CFR Part 11 compliant software for secure electronic records and signatures.*

- Can test multiple packs simultaneously

- Operator-independent results

- Integrated vacuum pump and control systems

Benefits:

- Precise & Reliable: High precision in detecting micro leaks. Consistent and reliable results.

- Adaptable & User-friendly: Adaptable for different sizes and shapes. Easy to operate.

- Efficient: Fast and efficient, suitable for high-volume testing.

Technical Specifications:

- Dimensions and Weight: 630 x 705 x 333 mm (L x W x H), 40 KG

- Materials: Stainless steel, Anodized aluminium, Polycarbonate, Rubber

- Power Supply: 100 – 230V 50/60HZ

- Air Supply: > 5.5 – < 8 bar

- Air Consumption: 150 Nl/min

- Compliance and IP Rating: CE, IP20, 21 CFR Part 11 (Software)

- Size Measuring Chamber: 350 x 500 x 116 mm (L x W x H)

- Leak Detection Method: ASTM F2338

- Minimum Leakage: > 0.9 cm3/min

- Maximum Testing Capacity: 2P/M

- Connections: USB/Ethernet export, 24VDC logic (free programmable)

- Packaging Type and Size: MAP up to 350 x 500 x 116 mm (L x W x H)

*Compliance with 21 CFR Part 11:

- Electronic Records: Ensures secure and reliable storage of all test data, preventing unauthorized access or modifications.

- Audit Trail: All user actions and data entries are recorded with timestamped logs, supporting full traceability.

- Electronic Signatures: Supports digital signature functionality to verify and approve tests electronically.

- Access Control: Multi-level user authentication with role-based permissions to ensure that only authorized personnel can operate the SLT or modify critical settings.