Leak Tester

The Oxipack Can Leak Tester (CLT) is a versatile solution designed for testing various types of cans, including metal and composite carton cans, with or without paper labels. Utilizing the vacuum decay method for leak testing, the CLT's patented, FDA-approved flexible membrane is pre-formed to match the shape of the packaging. This design allows for creating a small measuring space around the packaging and a deep vacuum in the test chamber, ensuring the protection of seals and contents.

Designed to handle a variety of rigid products like vials, bottles, pods, capsules, cans, and jars, the Oxipack Container Closure Integrity Tester employs a vacuum decay method for effective and non-destructive leak detection

Leak Tester

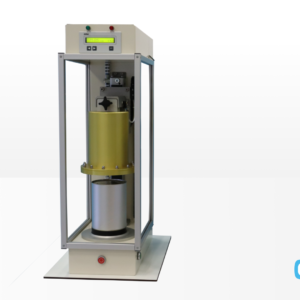

The Oxipack Multi Leak Tester (MLT) offers a versatile and efficient solution for testing various rigid products like pods, capsules, cans, jars, bottles, vials, and cups. Embracing a broad spectrum of dimensions and shapes, the MLT employs the vacuum decay method for leak testing, ensuring a comprehensive assessment of the entire packaging. It's tight fit rigid part is pre-formed to precisely fit the packaging, creating a minimal measuring space and a deep vacuum in the test chamber. This feature allows the MLT to adeptly detect both micro-leaks and larger leaks, maintaining the integrity of the packaging and seals. The MLT's ability to adapt to different package sizes and filling weights makes it an invaluable tool for industries requiring high-precision leak testing, delivering direct, accurate, and non-destructive results.

Leak Tester

The Oxipack Bottle Leak Tester (BLT) is a specialized solution designed for testing a diverse range of bottles, catering to different dimensions and shapes. Utilizing the vacuum decay method, the BLT ensures that every part of the bottle, from the top to the entire structure, is thoroughly tested for leaks without compromising the contents. The BLT's unique measuring head creates an optimal closure around the bottle, allowing for the detection of both significant and minute leaks. The pre-formed design of the tester matches the exact shape of the packaging, ensuring a protective embrace and meticulous accuracy. This non-destructive, user-friendly, and robustly designed tester is integral for maintaining the integrity of bottled products, proving indispensable in quality control processes.

Leak Tester

The Oxipack Stationary Leak Tester (SLT series) is a non-destructive leak detection system using vacuum decay technology in compliance with ASTM F2338. It is designed for both flexible MAP packaging and rigid formats such as coffee capsules, trays, cups, and food pouches. The SLT uses flexible rubber membranes for soft packs, while the SLT XS employs custom-molded rigid plates for shaped products. Both models offer fast, accurate, and operator-independent results—ideal for seamless integration into automated quality control processes.

Oxipack's standard solution for testing a wide range of flexible packaging, the SLT combines efficiency and accuracy in leak detection for maintaining product quality.

Leak Tester

The Oxipack Stationary Leak Tester R&D uses vacuum decay (ASTM F2338) for non-destructive testing of flexible (MAP) packaging. It ensures accurate detection of leaks, features a user-friendly touchscreen, and can test multiple packs simultaneously with instant, objective results.

Leak Tester

The Oxipack Vacuum-Sealed Leak Tester (VSLT) is specifically designed for detecting leaks in vacuum-sealed packaging, ideal for products like vacuum-packed sausages. It can test packaging immediately after production, identifying even the smallest micro leaks. The VSLT is particularly useful in the meat industry, where leak detection is crucial for product quality and shelf life. The machine features a built-in vessel and vacuum pump, creating a deep vacuum in a small measuring space around the packaging. This enables the VSLT to detect both micro and larger leaks in a non-destructive manner. Additionally, its capacity to test various packaging shapes and sizes, thanks to customizable inserts, makes it a versatile and essential tool for quality assurance in vacuum-sealed products.

Block "news" not found