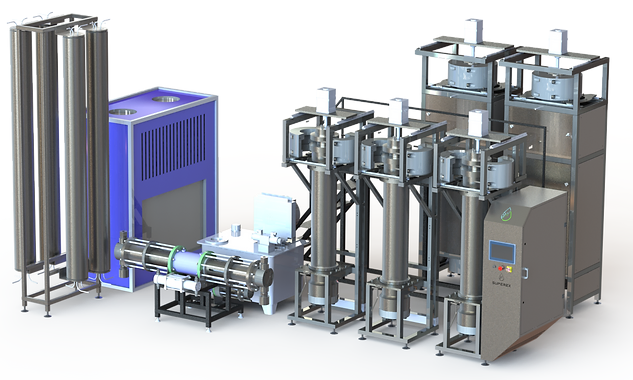

MODEL: P-200

SPECIFICATION

- Extraction Vessel Volume: 100 L (or 100×100 L)

- Special design for efficient industrial production

- 3 Separators Each with a Volume of 35 L

- Two separators with pressure and temperature control

- Separators have interchangeable nozzles for cyclone flow or liquid trap

- Maximum Working Pressure: 345 bar Maximum Working Temperature: 70°C

- High CO₂ Flow Rate (10 kg/min)

- Co-solvent Feed System (1 L/min)

- Fully Automatic Pressure Increase, Solvent Feed, and Pressure Reduction

- High-Precision PID Algorithm for Temperature Control Fully Automatic Pressure Regulators

- Fully Automatic Adaptive Control of CO₂ Pressure and Flow

- Fully Automatic CO₂ Liquefaction and Recirculation System for Reuse with Efficiency Up to 99%

- High-Efficiency Heat Pump (COP=6)

- Increase of the maximum pressure up to 600 bar (test pressure 900 bar)

- Increase of the maximum extraction temperature up to 90°C

- Additional extraction vessel with a volume of 100 L

- Cooling package for the first or third separator (operator’s choice) down to -10°C for more efficient fractionation

- Coriolis flow meter by Bass Instruments

- Annual Spare Parts and Accessories Kit (ZIP)