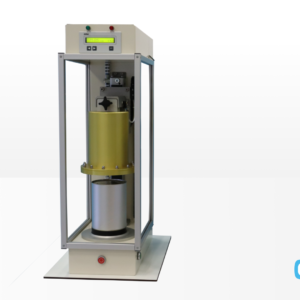

The Oxipack Multi Leak Tester (MLT) offers a versatile and efficient solution for testing various rigid products like pods, capsules, cans, jars, bottles, vials, and cups. Embracing a broad spectrum of dimensions and shapes, the MLT employs the vacuum decay method for leak testing, ensuring a comprehensive assessment of the entire packaging.

It's tight fit rigid part is pre-formed to precisely fit the packaging, creating a minimal measuring space and a deep vacuum in the test chamber. This feature allows the MLT to adeptly detect both micro-leaks and larger leaks, maintaining the integrity of the packaging and seals. The MLT's ability to adapt to different package sizes and filling weights makes it an invaluable tool for industries requiring high-precision leak testing, delivering direct, accurate, and non-destructive results.