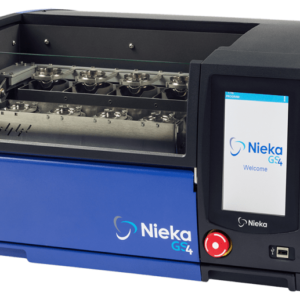

Nieka E Series – Fusion Machine for XRF and ICP Preparation

Full temperature range for no-compromise methods – Perfect for ICP and XRF sample preparation

The Ultimate electric fusion

At NIEKA®, we used our strong experience from the fusion industry and forged an instrument that is the perfect fit for the most demanding industrial fusion laboratories. Downtime is your enemy, and using the best tool is your only way to remain on top and deliver results on time.

For the past years, we spent thousands of hours to bring reliability and flexibility to electric fusion. We created a new range of products based on the unique and proven Nieka® platform in conjunction with all the latest manufacturing technologies to create these easy-to-maintain and powerful instruments.

You will be able to create perfect fusion methods based on chemistry and not instrument limitation. This will save you time and allow your lab to obtain perfect fused samples, every time.

-

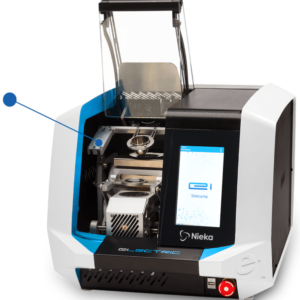

Clip-on heating modules for instant maintenance, change heating modules in seconds when a repair is needed. The module can be kept on the shelf for instant maintenance without interrupting your workflow.

-

Powerful fan units for rapid cold-to-cold operation, better airflow allows keeping the electronics cool at all time and reducing your cycle time by having a faster cooling step at the end of the cycle.

-

Very large and intuitive interface, the intuitive touchscreen allow you to operate the instrument, browse and edit programs and edit instrument settings. It’s a simple, yet powerful feature that allows you to get the most of the instrument in seconds.

-

USB and network for upgrades and backups, the instruments connectivity allows you to share and archive your fusion programs easily without additional software.

-

Circular stirring motion for faster sample dissolution, the unique circular stirring motion allows a better and faster dissolution of your samples. You will achieve better repeatability, higher success rate and shorter fusion cycles.

Level up with E3

The E3 brings modular fusion to a new level. All heaters and controls are built in modules and it allows running 3 samples per cycle.

Perfect temperature control in each fusion chamber

Each position has its own heater, thermocouple and control, allowing redundancy and perfect temperature control.

Clean-air channel for contamination-free operation

The cooling air is filtered, allowing contamination-free sample preparation. Keeping the dust away also reduces the occurrence of cracked and crystalized glass disk.

Technical Specification

|

Feature |

E1 |

E2 |

| Power |

208-240Vac.50-60Hz 1PH, up to 2kW heating power |

208-240Vac.50-60Hz 1 or 3PH / 380-415 Vac.50-60 Hz 3 PH, up to 6kW heating power |

| Dimension (W, H, D) |

45 x 40 x 60 cm; 50 kg |

70 x 40 x 63 cm; 64 kg |

| Heaters |

High-emissivity resistive heaters |

|

| Programming |

Up to 32 steps per program; 32 program storage space + external USB |

|

| Mixing |

Clockwise and counter-clockwise agitation, fully configurable |

|

| Heating configuration |

25-1275oC temperature for each step |

|

| Bead cooling |

Fully configurable cooling steps, from 0 to 100% |

|

| Heater servicing |

Modular crucible and mold heaters with quick connectors |

|

| Connectivity |

USB/LAN connectivity |

|

| XRF / ICP sample preparation |

Bead-solution switch using modular system (no tool required) |

|

| Ventilation requirement |

No full hood required, 3 m3 / min. extraction point |

No full hood required, 7 m3 / min. extraction point |