Based on visual measurement principle with precision image analysis algorithms, equipped with double telecentric optical lens with high depth of field, VX3000 series of Flash Measuring Machines achieve fast dimensional measurement by one-key operation. VX3000 series are suitable for precise dimensional measurement in the fields of machinery, electronics, molds, injection molding, hardware, rubber, low-voltage electrical appliances, magnetic materials, precision stamping, connectors, connectors, terminals, mobile phones, home appliances, printed circuit boards, medical equipment, watches, cutting tools, etc.

Based on visual measurement principle with precision image analysis algorithms, equipped with double telecentric optical lens with high depth of field, VX3000 series of Flash Measuring Machines achieve fast dimensional measurement by one-key operation. VX3000 series are suitable for precise dimensional measurement in the fields of machinery, electronics, molds, injection molding, hardware, rubber, low-voltage electrical appliances, magnetic materials, precision stamping, connectors, connectors, terminals, mobile phones, home appliances, printed circuit boards, medical equipment, watches, cutting tools, etc.

Parameters

| Model No. | VX3200 | VX3300D | ||

| Image Senor | 5MP CMOS | |||

| Monitor | Built-in | 10.4″ LCD (XGA:1024×768) | ||

| Outside | 24″ LCD (XGA:1920×1080) | |||

| Acceptance Lens | Double Telecentric Lens | |||

| Light | Ring light | Four-segment illumination(White Light) | ||

| Bottom light | Telecentric transmission illumination(Green Light) | |||

| Field of View | Large field | 200×200mm(4 Angle R50) | 300x200mm(4 Angle R50) | |

| High precision | 130×130 | 230×130mm | ||

| Resolution | 0.1um | |||

| Repeatability of Image Meas. |

Wide Field | Without Stitching*1 | ±1um | |

| With Stitching*2 | ±2um | |||

| High Precision | Without Stitching*1 | ±0.5um | ||

| With Stitching*2 | ±1.5um | |||

| Accuracy of Image Meas. |

Wide Field | Without Stitching*1 | ±5um | |

| With Stitching*2 | ±(7+0.02L)μm | |||

| High Precision | Without Stitching*1 | ±2um | ||

| With Stitching*2 | ±(4+0.02L)μm | |||

| Height Meas. (Optical probe) (Optional) |

Measuring Range(X*Y) | / | 120×110mm | |

| Max Hole-Depth Ratio(h/φ) | / | 1.64 | ||

| Dia. of Beam | / | Φ100μm(Φ18μm optional) | ||

| Resolution | / | 0.25μm | ||

| Z Non-movement | Range(Z) | / | ±2mm | |

| Accuracy | / | ±2μm | ||

| Z Movement | Range(Z) | / | 75mm | |

| Accuracy | / | ±(6+0.01H)μm, H is Z moving height in mm | ||

| XY Object Table | X Travel Range | 110mm | 210mm | |

| Y Travel Range | 110mm | |||

| Loading Capacity | 7.5kg | |||

| Z-Axis Travel Range | 75mm(Motorized) | |||

| Size(LxWxH) | 531×386×731mm | 531×503×731mm | ||

| Weight | 49kg | 75kg | ||

| Input | AC100~240V, 50~60Hz,2A,300W | |||

| Working Environment | Temp.10℃~35℃, Humidity 20%~80%, Vibration<0.002g, Less than 15Hz | |||

Remark:

*1 In the focus position, the environment temperature is +20 °C ± 1.0 °C

*2 In the focus position, the environment temperature is +20 °C ± 1.0 °C, and the load on the table is 2 kg or less; L is the moving range of the table (mm)

Statistics

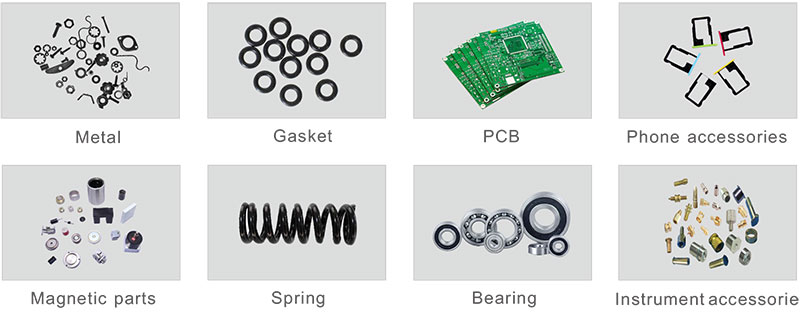

More Applications