The A Series MICRO XRF is designed for precise measurement of the smallest X-ray features in semiconductors and microelectronics. The system supports large PCBs and wafers of any size, with a 7.5 μm FWHM X-ray beam—the smallest in the world for XRF. A dual-camera system with 140X magnification provides detailed imaging, while a programmable X-Y stage moves up to 600 mm with ±1 μm precision. Pattern recognition, auto-focus, and 3D mapping optimize measurement accuracy.

The W Series Micro XRF from Bowman features a 7.5 µm FWHM X-ray beam, the smallest in the world for coating thickness analysis using XRF technology. This makes it ideal for measuring small components like BGAs and solder bumps. It includes a dual-camera system with 140X magnification for precision imaging and a secondary camera for live viewing. A programmable X-Y stage with ±1 µm accuracy, along with pattern recognition and auto-focus, enables precise measurements and automated multi-point analysis. The system also offers 3D mapping for coating topography visualization. Standard configurations include a molybdenum anode tube (with optional chromium or tungsten) and a high-resolution Silicon Drift Detector. The instrument can measure up to five coating layers simultaneously and operates with Archer software, which streamlines measurement, reporting, and application setup.

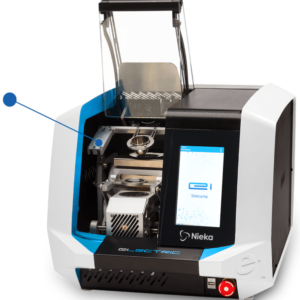

Nieka Core 6 – Fusion Machine for XRF and ICP The Core-6 is the achievement of a decade-long research program where nothing has been left behind. With the Core systems, you will benefit from multiple inventions and the experience of Nieka users worldwide. The Core-6 mechanical systems are based on the proven Nieka platform: they...

Sample Preparation

Nieka E Series – Fusion Machine for XRF and ICP Preparation Full temperature range for no-compromise methods – Perfect for ICP and XRF sample preparation The Ultimate electric fusion At NIEKA®, we used our strong experience from the fusion industry and forged an instrument that is the perfect fit for the most demanding industrial fusion...

Sample Preparation

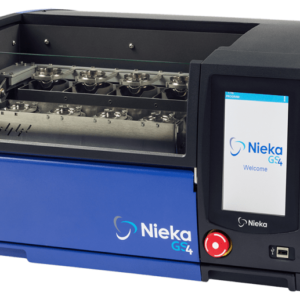

Nieka G Series – Fusion Machine for XRF and ICP Preparation The solution for HIGH-THROUGHPUT FUSION laboratories AT Nieka, we used our strong experience from the fusion industry and forged an instrument that is the perfect fit for the most demanding high throughput fusion laboratories. Downtime is your enemy and using the best tool is...

The B Series is a basic XRF measurement system with a top-down design for easy operation. It features a fixed sample stage, requiring users to manually align the test position using video imaging. The sample chamber is similar to the P Series but without a programmable X-Y stage. The system includes a fixed collimator, fixed-focus camera, SDD detector, and a durable micro-focus X-ray tube. Notably, the B Series can be upgraded with additional collimators or a variable-focus camera to enhance analytical flexibility.

The G Series XRF is an ideal choice for laboratories and production lines, especially for users with limited workspace, budget constraints, or a preference for "bottom to top" operation with motorized Z-axis control. Designed to efficiently analyze small samples quickly and easily, this system offers flexibility and high performance in material inspection and evaluation.

The K Series is a high-precision XRF system designed for diverse sample analysis, featuring a large 12″ x 12″ measurable area, programmable X-Y stage, and auto multi-collimator for flexible spot sizes. Its variable-focus camera (0.25″ to 3.5″) and table view navigation enable effortless measurements. For ultra-small features, the poly-capillary optics version offers 15μm resolution, high-precision stage (2µm), and 140x magnification camera with digital zoom. Equipped with an SDD detector and long-life X-ray tube, it ensures accuracy and compliance with ASTM B568, ISO 3497, and IPC-4552