PILOT-SCALE & MID-SIZE MILLING PLATFORM – QUADRO

The mid-sized SDx milling and screening platform from Quadro offers two pilot-scale processing solutions on a single common drive, providing a seamless transition from laboratory research to actual production. This solution is ideal for customers with smaller-scale production requirements, complementing Fitzpatrick & Quadro’s versatile range of interchangeable milling and screening solutions. Equipped with SMARTdetect™ technology, it allows rapid head changes and automatic RPM adjustments.

SUITABLE FOR:

OSD Pharma, Nutraceuticals, Food, Chemical, Cannabis, API Pharma

FLEXIBLE MILLING AND SCREENING HEADS FOR QUADRO SDX PLATFORM

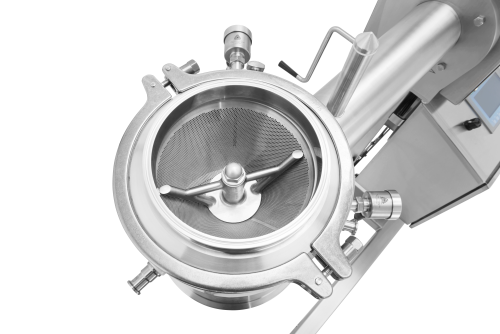

U10x Comil® – Conical Milling

Key Benefits:

Key Benefits:

- Results achieved with the classic U10 pilot model are duplicated and enhanced with the upgraded U10x.

- Greaseless gearbox reduces contamination risk and lowers operational temperatures.

- Achieve tighter particle size distributions (PSDs), improving on-target performance by 20–40%.

- Patented high-efficiency screens offer capacity increases up to 50% and lower product temperatures up to 30% (depending on material).

- Fully compatible with Classic U10 screens and impellers, reducing tooling costs.

At a glance:

- Greaseless gearbox

- High-efficiency screen options

- Enhanced CIP functionality

- Tooling compatibility with Classic U10

- Lab-scale model available (SLS Series)

- Production-scale model available (SDx Series)

S10x FlexSift – Security Screening

Key Benefits:

- Security screening system replaces multiple traditional vibratory sifters while delivering similar capacities.

- Market-leading capacity with 40–50% higher throughput compared to comparable technologies.

- Optimum capacity range superior to other centrifugal security screeners available.

- Greaseless gearbox eliminates contamination risks.

At a glance:

- Greaseless gearbox

- Lab-scale model available (SLS Series)

- Production-scale model available (SDx Series)