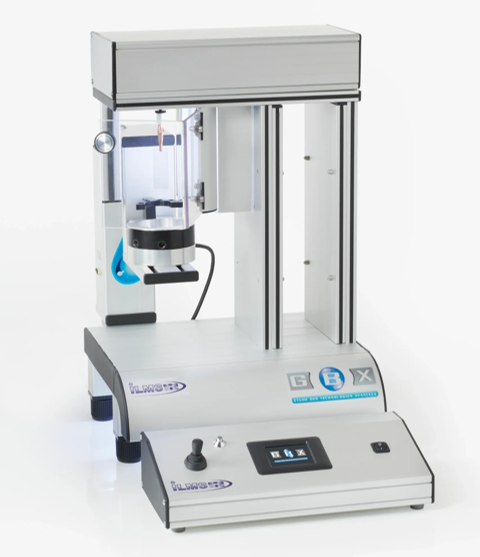

Interfacial Tension Tensiometer GBX

Introduction

Due to the paramount significance of obtaining precise measurement results in this particular type of analysis, GBX Scientific has successfully resolved a significant challenge related to achieving accurate interfacial tension measurements.

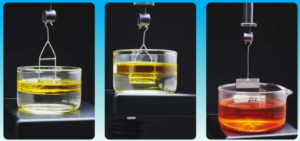

Explanation: When a liquid is introduced onto another liquid, molecular constituents from one liquid have a tendency to migrate to the other liquid, and vice versa. This phenomenon leads to an evolution of the interfacial tension over time. Consequently, it is imperative for the operator to discern the optimal values and understand the underlying reasons for their validity.

GBX Instrumental Solution

Some of the primary benefits of the instruments include:

- Automatic measurement regardless of the liquid level in the beaker

- Manual sensor calibration with edition of an automatic report calibration

- Optional automatic sensor calibration at any predefined value, determined by the operator, to ensure optimal accuracy.

- Extremely low speed, operating at a few micrometers from extraction, ensuring precise accuracy.

- Accurate displacement of the beaker without any vibrations, ensuring reliable measurements.

- Elimination of the need for manual mechanical preadjustment, simplifying the instrument setup process.

- Fully ASTM D 971-12 & ASTM D1331 Compliant

- Theories Harkins-Jordan & Zuidema-Waters included

- A touchscreen and joystick allow for controlling the instrument without the need for a PC.

- Our optional density kit is very easy to clean and perfectly calibrated. It is supplied with a certificate of calibration for better traceability of the measurements. The material has limited capability of being scratched easily to avoid false results, as might happen with other materials used for density measurements.

- Our optional dispenser helps in dispensing the oil on water without the risk of breaking the interface.

- A stirrer is available as an option when a mixture of liquids is required.

- An optional external printer can be connected to the control box in order to print the values of date and time, temperature, and interfacial tension at the end of the measurement for traceability.

In standard the instrument is supplied with:

- A control box featuring a display of all parameters and the measurement of Interfacial tension

- Illuminated area

- 7 inch inch touch screen display

- 1 off Du-Nouy Ring

- Possible to use a PC to control the instrument without the need to get a cable between PC and instrument

The software is fully customizable, allowing you to create your own measurement steps if the default wizard does not meet your requirements or if any ASTM or ISO procedures need to be modified in the future. This will ensure our user to be updated.

Loop of interfacial measurements is available as standard procedure to repeat the measurements

SPECIFICATIONS OF THE STANDARD INSTRUMENT

| Category | Parameter | Min | Max |

|---|---|---|---|

| Motorization | Speed (µm/s) | 0.1 | 10000 |

| Maximum load (g) | 200 | ||

| Display resolution | 0.01 | 0.1 | |

| Range (g) | 200 mg | 100.000 g | |

| Manual calibration | Inc. | ||

| GBX easy attachment system | Inc. | ||

| Measurements | Range (mN/m) | 0.5 | 1000 |

| Accuracy (mN/m) | +/- 0.1 | ||

| Resolution (mN/m) | 0.01 | 0.01 | |

| Density | Range (g/cm³) | 0 | 3 |

| Density resolution (g/cm³) | 0.0001 | 0.0001 | |

| Temperature | Sensor type | PT100 | |

| Accuracy (°C) | 0.1 | ||

| Temp Ctrl | Temperature range | -10°C | +100°C |