|

Model |

Internal Volume (L) | Inner Dimensions (W×H×D, mm) | Outer Dimensions (W×H×D, mm) | Temperature Range (°C) | Pressure Range (kPa) | Power (kW) |

Cooling Water (t/h) |

|

VTL360-40W |

360 | 600×750×800 | 110×900×1900 | -70 to 160 | Constant to 0.5 | 15 |

0.4 |

|

VTL720-40W |

720 | 800×900×1000 | 1310×2050×2200 | -70 to 160 | Constant to 0.5 | 20 |

0.4 |

|

VTL1000-40W |

1000 | 1000×1000×1000 | 2510×2150×2200 | -70 to 160 | Constant to 0.5 | 20 |

0.4 |

|

VTL2370-40W |

2370 | 1300×1300×1400 | 1810×2450×2650 | -70 to 160 | Constant to 0.5 | 28 |

0.4 |

Additional Specifications:

-

Temperature Fluctuation: ±0.3°C (constant pressure).

-

Temperature Deviation: ±2.0°C (constant pressure).

-

Pressure Deviation: ≤±0.1 kPa (≤2 kPa), ≤±5 kPa (2–40 kPa), ≤±2 kPa (≥40 kPa).

-

Temperature Rise Time: 25°C to 160°C ≤60 min (constant pressure).

-

Temperature Fall Time:

-

25°C to -65°C: ≤45 min (VTL360-40W), ≤60 min (VTL720-40W, VTL1000-40W), ≤90 min (VTL2370-40W) at constant pressure.

-

-

Pressure Drop Time: Constant pressure to 0.1 kPa (dry chamber): ≤20 min (VTL360-40W), ≤25 min (VTL720-40W), ≤30 min (VTL1000-40W), ≤45 min (VTL2370-40W).

-

Material: Inner chamber (SUS304 stainless steel), outer chamber (manganese steel with electrostatic powder coating), thermal insulation (vacuum-special composite pressure-bearing material).

-

Actuators: Magnetic coupling transmission axial fan, low-noise piston/scroll compressor, nickel-chrome electric heater.

-

Operating Environment: Temperature (5–36°C), Humidity (30–85%RH), Pressure (86–106 kPa).

-

Power Supply: 380V ±38V, 50Hz ±0.5Hz, 3-phase 4-wire with earthing protection.

-

Notes: Optional quick pressure relief; internal or external pressure options; humidity function available for VTH models.

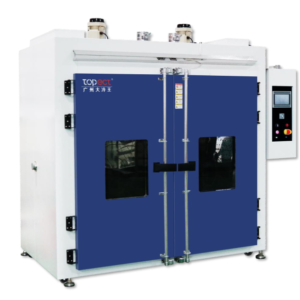

Product Features

-

Customizable lead holes on both sides for apparatus placement.

-

Unique lever lock design for secure sealing.

-

Power supply control terminal for samples.

-

Triple independent over-temperature protection.

-

Observation window for monitoring test samples.

-

45° air vents with adjustable guide vanes for temperature uniformity.

-

Modular refrigeration, waterway, and electrical systems for safety and maintenance ease.

-

Stainless steel inner chamber (SS304) and manganese steel outer chamber with electrostatic coating.

Refrigeration System

-

Uses low-noise piston or scroll compressors (Copeland, Bock, or Bitzer).

-

Environmentally friendly refrigerants (R404A, R23) with zero ozone depletion.

-

Equipped with filtration devices for long-term reliability.

-

Intelligent control optimizes power consumption.

-

Modular production for easy installation, debugging, and maintenance.

-

Pipelines protected with nitrogen during welding, with varnish-coated weld joints.

Control System

-

Topect Touch-Type Controller: 7″ TFT true-color touch screen (800×480 resolution), PLC-based with temperature and humidity modules.

-

Features: Simplified Chinese/English interface, fixed and program modes with 50 sections and 32,000 cycles, USB interface for data export, RS485/LAN/GPRS for remote monitoring.

-

Data Acquisition: Stores 3 months of data (1-minute sampling), supports CSV export via USB, optional PC connection for real-time monitoring.

-

Safety Features: Fault alarm with cause and handling prompts, timed startup/stop, power failure protection, user permission, and screen lock functions.

Standard Configuration

-

Vacuum-special electric heating observation window, 1 lighting lamp, 1 multiple air charging valve, 1 sample power supply terminal, 2 sets of sample holders, 1 external pressure testing port, 2 Φ80 cable port holes.

-

Safety devices: Leakage switch, motor/compressor protection, phase sequence, over-temperature protection.

Optional Accessories

-

Vacuum sealing connector (aviation socket).

-

Communication port and software for remote control/data transmission.

-

Customizable lead holes (Φ50, Φ80, Φ100, Φ160).

-

Temperature recorder.

-

Movable temperature sensor.

-

Custom sample cart.

-

Special load-bearing sample holder and bottom plate.

-

Non-standard customized equipment.