FULLY COMPUTERIZED TABLET PRESS – FLUIDPACK

Model: ACT series

Manufacturer: Fluid Pack

Origin: India

Key features

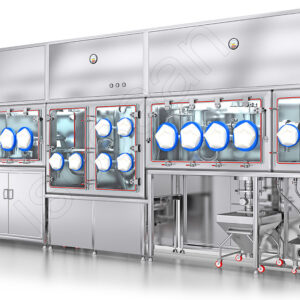

- Compact GMP-compliant design

- Square design with polished stainless steel lower guards and acrylic upper guards.

- Motorized pre-compression and main compression

- Pre-compression: 40 kN (4 tons).

- Main compression: 100 kN (10 tons).

- High precision

- Equipped with motorized dozer for precise depth of fill adjustment.

- Integrated load cells at pre-compression and main compression points for accurate monitoring.

- Advanced control system

- PLC with 15-inch industrial touch screen interface (IPC).

- Auto weight control (AWC) and auto rejection system for maintaining consistent tablet quality.

- Single and bi-layer capabilities

- Can produce single-layer and bi-layer tablets, with optional bi-layer attachment.

- Maintenance-friendly design

- Vibration-free operation at 50 RPM.

- All grease lubrication, no hydraulic oil leakage.

- Safety features

- Upper punch penetration with interlock switches on all guards for safe operation.

Specifications

| Feature | ACT-I 16 | ACT-I 20 | ACT-I 28 | ACT-I combo |

| Number of stations | 16 | 20 | 28 | 8D + 8B |

| Tooling type | D | B | BB | D + B |

| Output (tablets/hour) – single | 9600–48000 | 12000–60000 | 16800–84000 | 4800–24000 |

| Output (tablets/hour) – bi-layer | 9600–24000 | 12000–30000 | 16800–42000 | 4800–12000 |

| Max operating pressure – main | 100 kN | 100 kN | 100 kN | 100 kN |

| Max pre-compression pressure | 40 kN | 40 kN | 40 kN | 40 kN |

| Max tablet diameter | 25 mm | 16 mm | 11 mm | 25 + 16 mm |

| Depth of fill | 3–10 mm | 8.5–14 mm | 12.5–18 mm | 3–18 mm |

| Total power | 2.325 kW | 2.325 kW | 2.325 kW | 2.325 kW |

| Dimensions (closed guard) (cm) | 88W x 105L x 180H | 88W x 105L x 180H | 88W x 105L x 180H | 88W x 105L x 180H |

| Weight (approx.) | 1200 kg | 1200 kg | 1200 kg | 1200 kg |

Advanced features

- Auto weight control (AWC)

- Automatically adjusts tablet weight during production to ensure consistency.

- Auto rejection system

- Removes defective tablets based on weight and compaction force parameters.

- Bi-layer functionality

- Produces tablets with two distinct layers, enhancing tablet versatility and functionality.

- Industrial control panel

- Features a 15-inch touch screen interface for real-time monitoring and control.

- No hydraulics, no oil leakage

- Operates with grease lubrication only, minimizing maintenance and environmental concerns.

Applications

- Pharmaceutical R&D

- Ideal for developing formulations and small-batch production.

- Nutraceuticals

- Producing dietary supplements and herbal tablets with precise control.

- Specialty tablets

- Bi-layer tablets for combination drugs or functional tablets with multiple active ingredients.

The fully computerized tablet press (ACT series) is an innovative solution for research and small-scale tablet production. Its advanced motorized controls, bi-layer capabilities, and integrated safety features make it a versatile and reliable tool for pharmaceutical and nutraceutical industries.