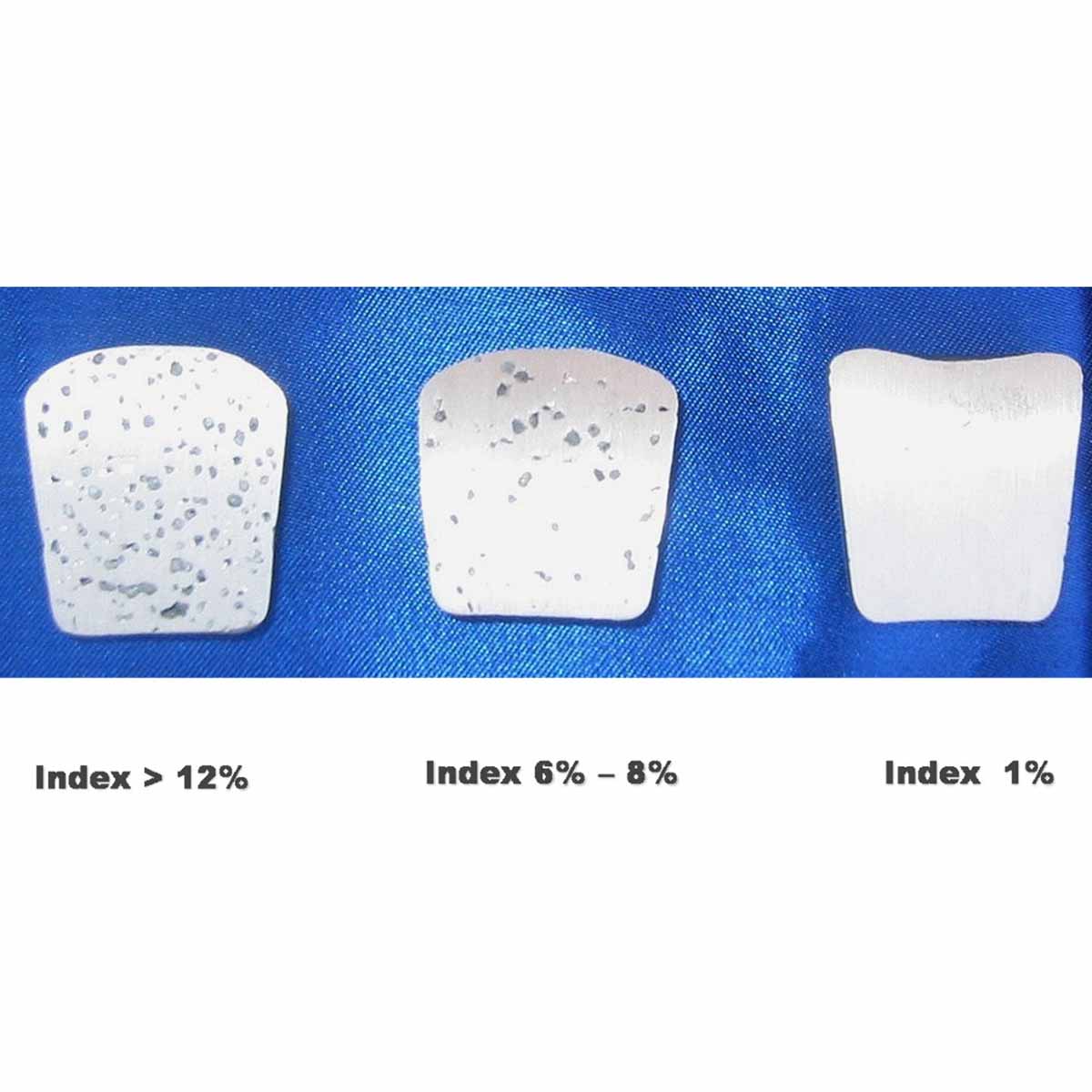

In foundries, especially for aluminium casting plants, the quality of molten metals is very important to assure the quality of the final cast product since impurities may negatively affect the quality of the cast.

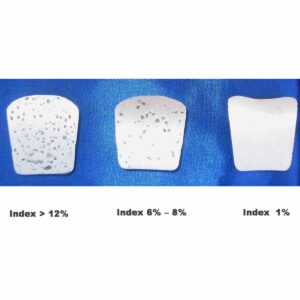

Defects created during the melting stage could create problems to the final micro-structure of the cast so is a mandatory step for the quality control department to check the quality of the melt.The density index represents the percentage difference in density between the two samples; the lower the density index the cleaner the aluminium melt and the fewer pores formed.

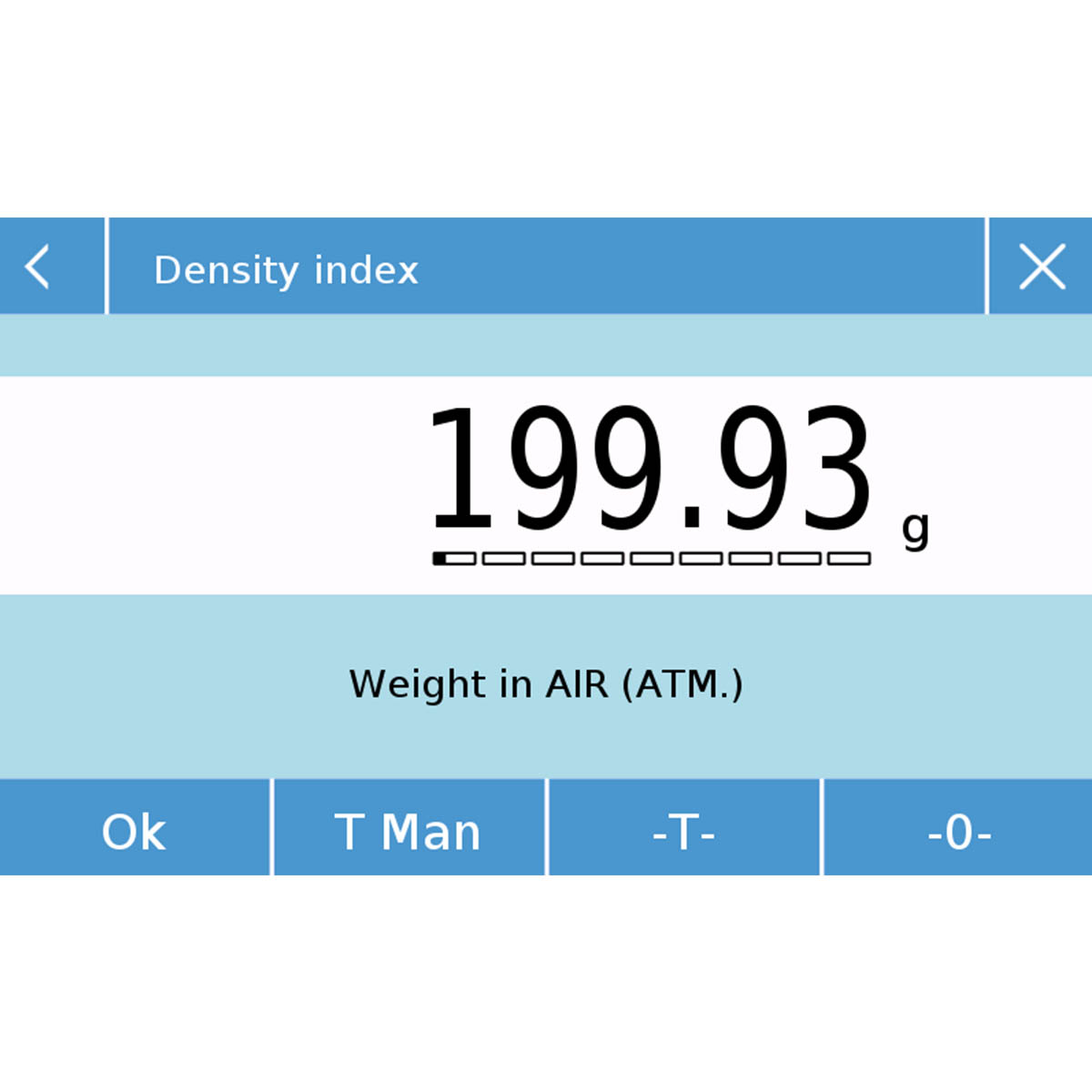

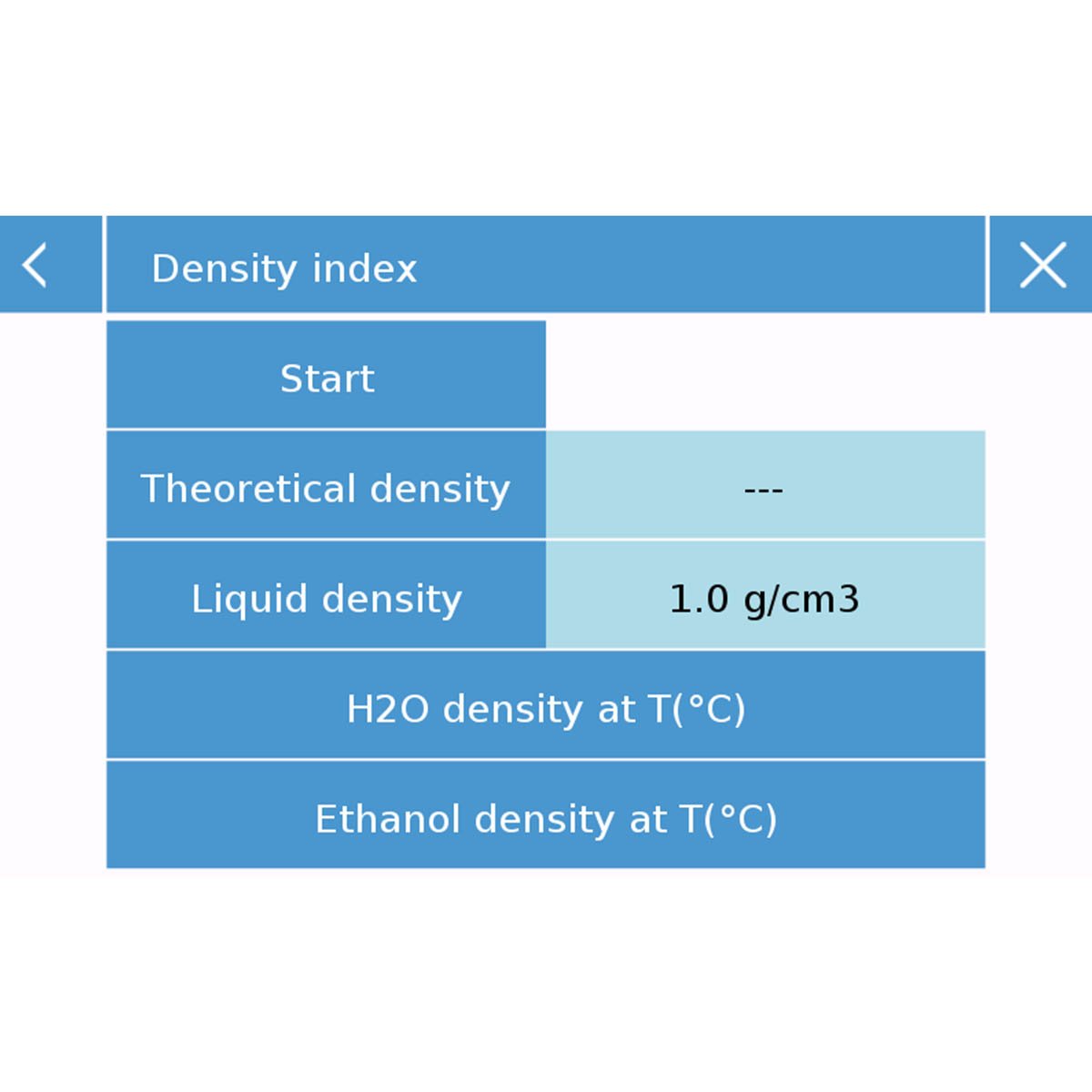

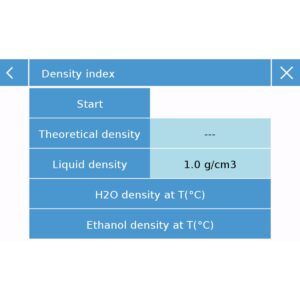

With BEL Engineering advanced balance M5-iDens, doing the density index measurement of a material is easy and fast. With a 5 inch touch screen interface, latest generation of microprocessors and intuitive user interface the user can have immediately accurate, clear and fast results.

Without the necessity to connect the balance to computer for using a software, all the data and results can be seen directly from the large touch screen of the balance, with the possibility to print also all the data with an optional printer.

Overview

- Electromagnetic force restoration weighing system

- 5 inch color touch screen display

- Easy and intuitive user interface

- Automatic internal calibration

- Efficient filtering to deliver quick and accurate results

- GLP compliance

- Multi-language

- Multi-user access protected by password

- Embedded Density Index calculation software, no need to connect the balance to a computer

Technical Features

| Capacity [Max] | 3100g |

|---|---|

| Resolution [d] | 0,01g |

| Calibration | Automatic internal |

| Pan size | Ø 80 mm |

| Repeatibility | 0,05 (g) |

| Linearity | ± 0,08g |

| Response time (sec.) | ≤2 |

| Verification | N/A |

|---|---|

| Minimum Load | 500 mg |

| Display | TOUCH-SCREEN 5” |

| Tare Range (Subtractive) | 3100 g |

| Span Drift In +10…+30°c | ± 3 ppm/°C |

| Interface | RS232 |

| Database Capacity | 3000 |

| Working Temperature | 5 – 35°C (15-30°C for verified models) |

| Power Supply | 110-230Vac. 50/60Hz, output 24V 1A 13VA |

| Power Consumption (Max) | 2 Watt |

| Calibrates With (Class) | 2000 g (F1) |

| Balance Dimensions (W X L X H) | 215 x 345 x 300 mm |

| Net Weight / Gross Weight, Approx. | 7 / 8,5 Kg |

| Package Size (W X L X H) | 390 x 520 x 630 mm |