Stability Chamber

The TOPECT Shock Series Test Chamber is designed for rapid temperature shock testing with high reliability and precision. Featuring a two-zone hot and cold design with fast vertical transfer, it ensures consistent thermal stress for product qualification.

Stability Chamber

The 3-Zone Cold and Hot Shock Test Chamber from TOPECT simulates rapid thermal changes across high, low, and ambient temperature zones to test product durability under extreme stress. With a swift zone-switching time under 10 seconds and recovery within 2–5 minutes, it ensures precise, repeatable performance. Engineered with stainless steel chambers, smart touchscreen + PLC control, and modular refrigeration, built tough with smart automation, this chamber is where innovation meets endurance.

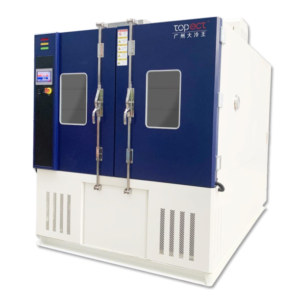

Stability Chamber

Topect’s environmental test chamber series is engineered to replicate extreme temperature and humidity conditions, making it ideal for assessing product reliability under demanding real-world scenarios. With a wide thermal range from −70 °C to +150 °C and precise humidity control between 20% and 98% RH, these chambers deliver high accuracy and consistent performance. Their sleek, user-friendly design ensures ease of operation and maintenance, making them a reliable solution for sectors such as electronics, automotive, pharmaceuticals, and advanced materials.

Stability Chamber

Specially engineered to simulate harsh environmental conditions, this test chamber combines high and low temperature capabilities with low pressure (vacuum) simulation. It’s an ideal solution for testing the durability, stability, and safety of materials, components, and finished products under extreme scenarios. Featuring advanced touchscreen + PLC control, a corrosion-resistant STS304 stainless steel inner chamber, modular refrigeration, and user-friendly design elements like a large observation window, lead-through ports, and a drawer-type water tank — this chamber offers a powerful, precise, and dependable testing experience.

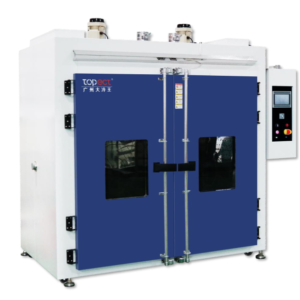

Stability Chamber

This equipment is specifically designed for long-term heat resistance testing of materials, components, and finished products under sustained high-temperature conditions. Built with a robust stainless-steel chamber, it features precise temperature control via a PID controller and ensures long-term stable operation. Durable, accurate, and highly reliable — it's an ideal solution for all thermal aging test applications.

Stability Chamber

This advanced chamber is purpose-built to simulate high-temperature, low-oxygen environments for evaluating material durability and oxidation resistance. Featuring a robust triple-layer insulation design and a direct-drive circulation fan, the system ensures uniform conditions throughout the chamber. Its smart control platform integrates real-time sensors, automated data logging, fault detection with alarms, and remote monitoring capabilities—making it an ideal solution for high-precision thermal and oxidative stress testing.

Stability Chamber

This is a temperature and humidity test chamber specifically engineered to simulate rapid thermal transitions at rates of 5 °C/min, 10 °C/min, or 15 °C/min. It enables high-precision evaluation of the durability and performance of materials, components, and finished products under extreme temperature and humidity fluctuations.

Stability Chamber

This integrated chamber is an advanced temperature–humidity–vibration test chamber that integrates precise thermal cycling (from –70 °C to +150 °C), high‑accuracy humidity control (20–98% RH), and an optional vibration table into a single unit. It features a robust STS304 stainless steel interior, modular refrigeration, intuitive touchscreen + PLC controls, and flexible design elements like large viewing windows, lead‑through ports, and drawer‑style water tanks. Ideal for comprehensive durability testing, it’s engineered for use in aerospace, electronics, automotive, and materials industries where multi‑stress simulations are crucial.

Block "news" not found