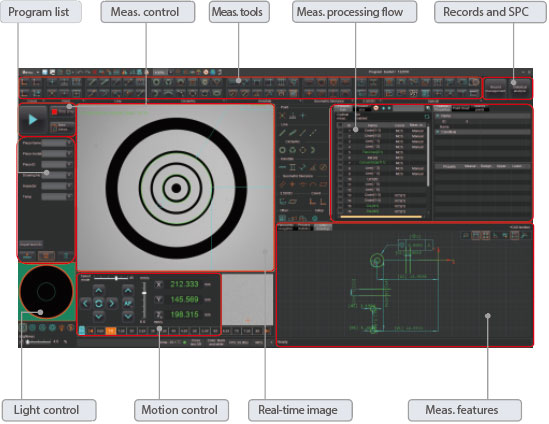

Functions

1. Measurement tools: Extracting edge points by scanning, extracting edge points by multi-segment, extracting edge points by circle, ellipse extraction, extracting contour line by frame selection, focus point, nearest points, etc.

2. Measure geometric features: Point, line, circle (center coordinate, radius, diameter), arc, center, angle, distance, line width, hole site, aperture, number of holes, distance from hole to hole, hole to edge, distance from the arc center to the hole, distance from the arc center to the edge, distance from the arc high point to the other arc high point, distance from the intersection to the intersection, etc.

3. Construction features: Intersection, center point, extreme point, endpoint, two-point connection, parallel line, perpendicular line, tangent, bisector, center line, line segment fusion, drawing circle by radius, drawing inscribed circle among three lines, drawing inscribed circle by two lines & radius , etc.

4. Geometric tolerance: Straightness, roundness, contour, position, parallelism, symmetry, perpendicularity, concentricity, and other shape and position tolerance evaluation.

Features

Replaceable RGB surface light Integrate 3D topography measurement

- Stable moving stage , high measurement accuracy

- Precision marble body, good stability and high precision.

- Precision linear slide rail and servo control system, smooth and silent movement.

- Three axes x/y/z programmable, realize batch inspection for complex features.

- Laser scanning imaging, 3D composite measurement

- Support spot-type laser probe to scan profile in height direction.

- Support 3D line-scanning laser probe.

- VisionX supports a variety of contour measurements and 3D spatial measurements, seamlessly connecting 2D/3D hybrid measurements.

- Strobe lighting source, high speed fly-shooting

- Equipped with strobe lighting source, support strobe and normal lighting modes.

- Support fly-shooting measurement mode, measurement efficiency is increased by 5~10 times.

- Support the stitching measurement function of the flash measuring machines.

- Replaceable RGB surface light, independent lifting up and down

- RGB and white light can be replaced to adapt to a variety of complex colors and material surfaces.

- The surface light can be lifted independently to better observe the sample surface.

- Support programmable back light, coaxial light and 6 rings and 8 segments of the surface light.

- Automatic and fast batch measurement

- The program matches the workpiece coordinate system and automatically executes the measurement process.

- Support CAD drawing and Gerber drawing import.

- Can execute quickly and accurate batch measurement in CNC fixed coordinate system mode.

- Easy operation, hassle-free

- Equipped with a large FOV navigation camera for fast workpiece positioning.

- Mechanical lens anti-collision function

- User-friendly operation interface, anyone can easily set and measure.

Software Interface

User-Friendly Operation Interface

Auto data export

Output SPC analysis report, which includes statistical values (such as CA, PPK, CPK, PP, etc.) and control charts (such as mean and range charts, mean and standard deviation charts, median and range charts, single value and moving range chart).

Can output Excel, Word, PDF, TXT reports and AutoCAD files.

Support exporting data to designated excel file according to designated template in real time

Support Q-DAS transmission according to designated format.

Support data exchanging via HTTP or socket protocol

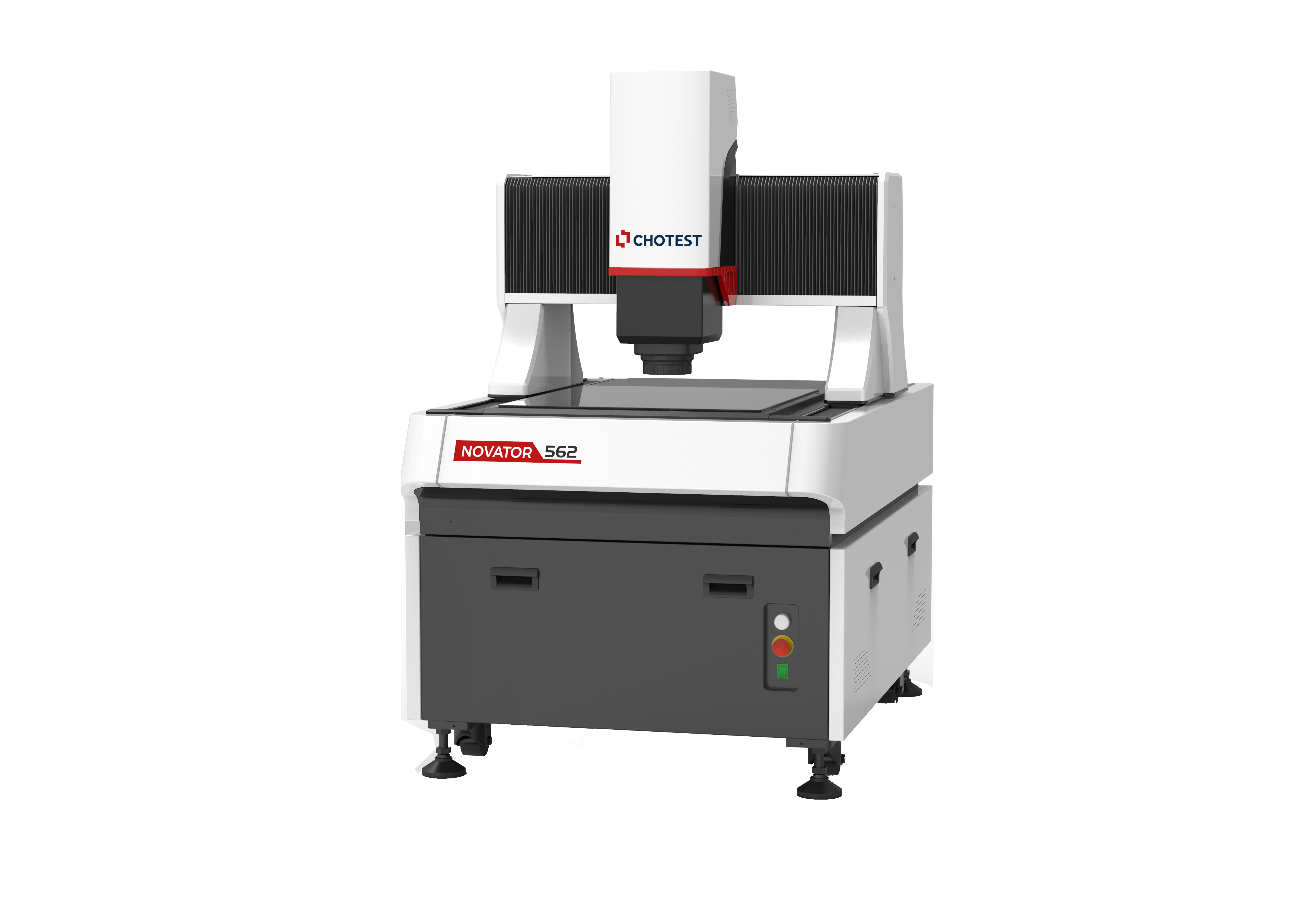

| Model No. | Novator562 | ||||

| Travel Range | X(mm) | 500 | |||

| Y(mm) | 600 | ||||

| Z(mm) | 200 | ||||

| Structure Type | Bridge | ||||

| Base Material | Granite | ||||

| Monitor | 24″ LCD(1920×1080) | ||||

| Image Sensor | 5MP High definition colorful industrial camera | ||||

| Resolution of Glass scale | 0.1μm | ||||

| Lens | 13.3X motorized lens | ||||

| Magnification | Optical Zoom: 0.6X~8.0X, Image Zoom: 17X~380X | ||||

| F.O.V. | Max: 13x11mm; Min:1.0×0.8mm | ||||

| Light | Back light | Telecentric transmission illumination | |||

| Ring Light | 6 rings and 8 segments (256 levels) surface light(or RGB surface light,Optional) | ||||

| Coaxial Light | LED | ||||

| Accuracy*1 | X/Y | (1.8+L/250)μm | |||

| X⊥Y | (2.2+L/250)μm | ||||

| Z | (3.0+L/200)μm | ||||

| Z measuring range*3 | 5mm | ||||

| 3D Scanning*2 | Scanning width*4 | 30mm | |||

| Repeatability*5 | ±1μm | ||||

| Z Accuracy*5 | ±0.1%F.S. | ||||

| Scanning speed | 10~80mm/s | ||||

| Fly-Shooting Mode | Support | ||||

| Navigation camera | Support | ||||

| Sensor Option | (1)Touch probe; (2)Optical probe | ||||

| Max Speed | XY | 500mm/s | |||

| Z | 100mm/s | ||||

| Size | 1100×1820×1700mm | ||||

| Weight | 1650kg | ||||

| Loading Capacity | 50kg | ||||

| Power | 2500W | ||||

| Motion Control | Servo control system | ||||

| Software | VisionX | ||||

| Input | AC200~240V, 50/60Hz | ||||

| Working Environment | Temp.20℃ ±2℃ , Humidity 20~80%, Vibration<0.002g, Less than15Hz | ||||

| *1 In the focus position, the environment temperature is +20 °C ± 1.0 °C, and the load on the table is 5 kg or less; L is the moving range of the table (mm) *2 Optional line-scanning probe is required. *3 Measuring range 5mm~40mm optional. *4 Scanning width 30mm~145mm optional. *5 Environment temperature is +20 °C ± 1.0 °C |

|||||