Stability Chamber

The PAC series of temperature and humidity chambers offers an excellent option for conducting cyclic tests involving low and high temperatures as well as humidity. These chambers are constructed with the highest quality and reliability, ensuring they can meet the rigorous testing requirements of various international standards such as ASTM, IEC, MIL, DIN, and more.

Stability Chamber

The PH140 TEMPERATURE AND HUMIDITY TEST CHAMBERS - FRIMED is a 1400L test chamber with precise temperature (10°C to +60°C) and humidity (20%-85% RH) control, ideal for laboratories and industrial applications. Its stainless steel interior, CFC-free insulation, and PID-controlled 9” touchscreen ensure efficiency and reliability. Equipped with a silent compressor, automatic fan stop, and safety thermostat, it meets European quality standards for stability testing and research

Stability Chamber

The PH70 is a 700L test chamber with precise temperature (10°C to +60°C) and humidity (20%-85% RH) control. It features a corrosion-resistant exterior, stainless steel interior, CFC-free insulation, and a PID-controlled 9” touchscreen. Equipped with safety features and an alarm system, it meets European standards, making it ideal for research and quality control.

Stability Chamber

The thermal chamber is equipped with the latest simulation technology to provide customers with an unparalleled testing experience. The chamber features a highly responsive touchscreen controller (Envicom Graphite Series) with a wide range of features, including Chamber Analytics, On-demand cooling, on-screen diagnostics, and safety alarms. It also integrates with networking ports such as Ethernet, RS 232, RS 485, and a 2GB SD card for test data storage. Additionally, the chamber can be integrated with third-party software such as NI/LabVIEW.

Stability Chamber

One of the major advantages of thermal cycling chambers is their high level of customization flexibility. The chamber utilizes a highly responsive touchscreen controller, the Envicom Graphite Series, which comes with a wide range of features. These include Chamber Analytics, On-demand cooling, on-screen diagnostics, and safety alarms.

Stability Chamber

After the fabrication of a high power photovoltaic (PV) module, the most critical aspect is the duration for which the module can produce useful power. Reliability and lifetime of photo-voltaic (PV) modules are key factors to system performance and warranty and thus are extremely important as far as PV business is concerned. Outdoor field testing is an accurate method in estimating module lifetime. However, since PV modules commonly come with twenty five years of warranty, testing modules in field for that long period is not feasible. Thus, due to time constraints, many accelerating aging tests have been derived over the years for testing reliability of PV modules. The accelerated test protocols established by organizations like IEC and UL have been adopted worldwide as official tests to evaluate module quality and reliability standards.

Stability Chamber

The thermal chamber is equipped with the latest simulation technology to provide customers with an unparalleled testing experience. The chamber features a highly responsive touchscreen controller (Envicom Graphite Series) with a wide range of features, including Chamber Analytics, On-demand cooling, on-screen diagnostics, and safety alarms. It also integrates with networking ports such as Ethernet, RS 232, RS 485, and a 2GB SD card for test data storage. Additionally, the chamber can be integrated with third-party software such as NI/LabVIEW.

Stability Chamber

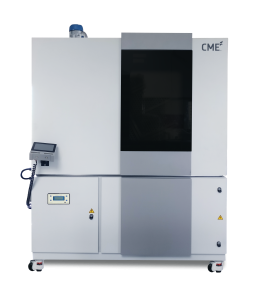

Tumbling Chamber for Ballistic Evaluation of Bullet Proof Jackets

A soldier’s most important means of preserving life and health are ballistic protection equipment such as a bulletproof jacket or helmet. Ergonomic is one of the important aspects of personal protection equipment which in this case is thermal stress caused using specific equipment. Testing (consists of three primary equipment one being CME’s Climatic Chamber) involves assessment of the Ballistic jacket’s thermal insulation properties to know what extent the jacket impedes the transmission of heat from the human body to its surroundings.