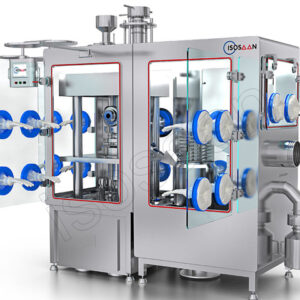

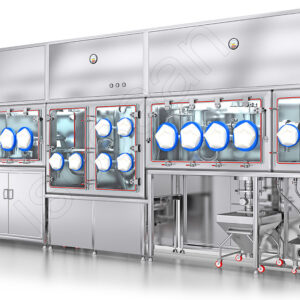

This is a Negative Pressure Isolator. This unit is used to house a special Tablet Compression Machine / Capsule filling machine that is containment compatible. IsoSaan has allies in the industry who can supply us with the required compression or capsule filling machines. These isolators are equipped with access barriers for Gloves that provides additional safety for the operator. Ideal system design can house mono block machines. For compression machines, the system can house a single or dual rotary machines. For Capsule filling, the system can house single station or multi station machines. This Isolator is also compatible with line machine that are typically use post compression and capsule filling. The Compression Isolator can be supplied with IsoSaans Smart LPU and IsoSaans Safe Dock assembly..... together the system ensures safe product charging assembly with zero risk for SBV assembly.

Isolator

- Valve Position Sensors (Normal or Intrinsic Save) : 5 Nos

- Valve Guiding Assembly : For accurate Docking / Undocking

- Electro Pneumatic panel : For valve operations / machine integrations

Isolator

IsoSaan provides static and dynamic flexible containment solutions. The system here is constructed of Polyurethane film that is 250 µm thick. This film is specially processed that provided excellent chemical & solvent resistance, as well as excellent anti-static properties. These systems are equipped with special Gas-tight zips for ease of ingress/egress. Flexible containment solutions can almost be used as an option for all Rigid negative pressure systems. The system has numerous advantages. Flexible Containment solutions are provided with chemical compatibility chart & several other options like BIBO Sleeves, Tri clover Bags, Continuous liners etc.

Isolator

This is a essential tool for in process validation of isolator Gloves. IsoSaan’s Portable Glove integrity testers provide accurate & consistent readings.

Isolator

This is a Negative Pressure Isolator completes a major share of manufacturing in Oral Solid Dosage Lines.

Isolator

This is Negative Pressure Isolator, based on the nature of the product. This is usually placed in the QC area & is used for intermediate Quality Testing during Manufacturing.

Isolator

This systems maintain an ISO Class 5 class in the Main Chamber during operation. This unit is used for carrying out sterile operations using a Laminar Flow system. The Isolator can be designed to handle operations like Sterile manufacturing, compounding, filtration, filling etc. It can also be used to house the complete injectable line. This Isolator can be used to envelop Sterility Manufacturing Machines. The Sterility manufacturing machines will be in Client's scope, but will be integrated & programmed by IsoSaan.

Isolator

This is a Negative Pressure Isolator that plays a pivotal role in almost all Pharmaceutical Industries like API Manufacturing, Formulations, OSD etc. The Isolator can carry out Sampling & Dispensing Activities.