Deskripsi

Mesin Pengukur Video Otomatis Seri CHT mencakup berbagai rentang pengukuran, menawarkan fungsionalitas yang kuat, dan mampu melakukan pengukuran presisi terhadap dimensi permukaan, kontur, sudut, posisi, serta toleransi geometris pada berbagai komponen kompleks.

Mesin Pengukur Video Otomatis Seri CHT dapat digunakan di berbagai industri seperti:

mesin, elektronik, cetakan, injeksi molding, perangkat keras, karet, peralatan listrik tegangan rendah, material magnetik, stamping presisi, konektor, plug-in, terminal, ponsel, peralatan rumah tangga, papan sirkuit cetak (PCB), peralatan medis, jam, pisau, serta bidang pengukuran dan pengujian.

Pembuatan laporan secara otomatis

Secara otomatis menghasilkan laporan analisis SPC dan mendukung integrasi data jarak jauh

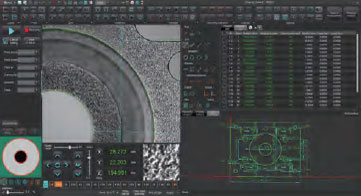

Fungsi Pengukuran

Alat Ekstraksi

Alat Ekstraksi

Pemindaian untuk mengekstrak titik-titik tepi, ekstraksi titik tepi multi-segmen, ekstraksi titik tepi melingkar, ekstraksi elips, pemilihan bingkai untuk mengekstrak garis kontur, titik fokus, titik terdekat, dan lain-lain.

Alat Anotasi

Alat Anotasi

Titik, garis, lingkaran (koordinat pusat, jari-jari, diameter), busur, pusat, sudut, jarak, lebar garis, posisi lubang, diameter lubang, jumlah lubang, jarak antar lubang, jarak dari lubang ke tepi, jarak dari pusat busur ke lubang, jarak dari pusat busur ke sisi, jarak dari titik tertinggi busur ke titik tertinggi busur lainnya, dan jarak dari titik perpotongan ke titik perpotongan, dan sebagainya.

Konstruksi

Konstruksi

Titik perpotongan, titik pusat, titik ekstrem, titik ujung, garis penghubung dua titik, garis sejajar, garis tegak lurus, garis singgung, garis pembagi sudut (bisektor), garis tengah, penggabungan segmen garis, lingkaran dengan jari-jari tertentu, lingkaran dalam dari tiga garis, lingkaran dalam dari dua garis dan jari-jari, dan sebagainya.

GD&T

GD&T

Evaluasi toleransi bentuk dan posisi seperti kelurusan (straightness), kebulatan (roundness), profil (profile), posisi (position), keseragaman sejajar (parallelism), simetri (symmetry), tegak lurus (perpendicularity), konsentrisitas (concentricity), serta toleransi bentuk dan posisi lainnya.

Koordinat

Koordinat

Sistem koordinat instrumen, titik ke garis, titik ke titik, garis ke garis, dan sistem koordinat benda kerja lainnya; sistem koordinat registrasi citra; dapat melakukan translasi, rotasi, dan penyesuaian manual pada sistem koordinat.

Alat Khusus

Alat Khusus

Radius R, jarak horizontal, jarak keliling, layar, celah, perbandingan kontur, pegas, O-ring, dan alat khusus lainnya untuk pengukuran cepat.

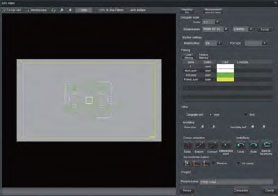

Mendukung pengaturan batch toleransi, klasifikasi skala, dan manajemen kustom warna.

Mendukung pengaturan batch toleransi, klasifikasi skala, dan manajemen kustom warna.

Mudah untuk dioperasikan.

Pengambilan gambar yang fleksibel dan perhitungan yang presisi.

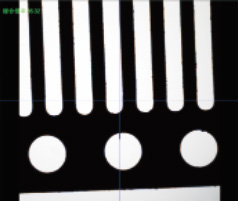

Mendukung pengendalian pemrograman segmen untuk cahaya permukaan, cahaya tembus, dan cahaya koaksial, secara otomatis mengidentifikasi posisi pengukuran, serta menghasilkan hasil pengukuran yang seragam dan stabil setiap kali.

Lampu cincin Cahaya latar Cahaya koaksial

Fitur permukaan terlihat jelas Mudah mengukur fitur profil Mengukur diameter lubang

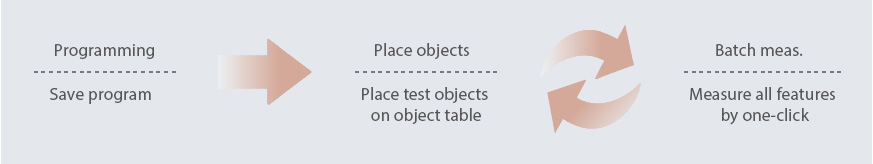

- Pengukuran batch otomatis.

- Program ini mencocokkan sistem koordinat dari benda kerja, secara otomatis menjalankan proses pengukuran, mendukung impor gambar CAD dan gambar Gerber, serta melakukan pengukuran dengan pencocokan sistem koordinat;

Dalam mode sistem koordinat tetap CNC, pengukuran batch dapat dilakukan dengan cepat dan akurat

Impor gambar CAD untuk membuat program Pengukuran batch CNC

Berbagai aksesori

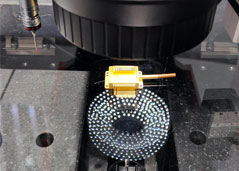

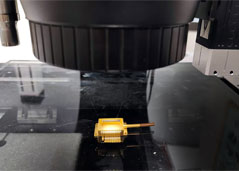

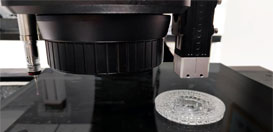

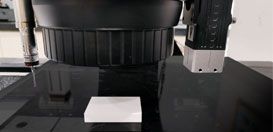

- Dilengkapi dengan probe sentuh atau probe optik untuk mengukur ketinggian dan ketelitian bidang, serta mewujudkan pengukuran ruang 2,5D.

Mendukung input eksternal dari kaliper digital dan pengukur tinggi.

Mendukung penggunaan printer label.

Pengukuran tinggi Pengukuran kelurusan permukaan

Hasil pengukuran tinggi Hasil pengukuran kelurusan permukaan

| Model No. | CHT452 | ||

| Travel Range | X(mm) | 400 | |

| Y(mm) | 500 | ||

| Z(mm) | 200 | ||

| Structure Type | Bridge | ||

| Base Material | Granite | ||

| Monitor | 24″ LCD(1920×1080) | ||

| Image Sensor | 1.6MP High definition colorful industrial camera | ||

| Resolution of Glass scale | 0.1μm | ||

| Lens | 8.3X motroized lens | ||

| Magnification | Optical Zoom: 0.6X~5.0X, Image Zoom: 27~229X | ||

| Light | Back light | Telecentric transmission illumination | |

| Ring Light | 6 rings and 8 segments (256 levels) surface light | ||

| Coaxial Light | LED | ||

| Accuracy*1 | X/Y | (2.5+L/200)μm | |

| X⊥Y | (3.0+L/200)μm | ||

| Z*2 | (4.5+L/200)μm | ||

| Max Speed | XY | 500mm/s | |

| Z | 100mm/s | ||

| Height Meas. (Optical Probe) (Optional) |

Measuring Range(X*Y) | 300*500mm | |

| Max Depth/Diameter(H/Φ) | 1.64 | ||

| Dia. of Beam | Φ100μm(Φ18μm optional) | ||

| Resolution | 0.25μm | ||

| Z Non-movetment |

Range(Z) | ±2mm | |

| Accuracy | ±2μm | ||

| Z Movetment |

Range(Z) | 200mm | |

| Accuracy | ±(6+0.01H)μm, H is Z movement height in mm | ||

| Size | 950×1320×1700mm | ||

| Weight | 1400kg | ||

| Loading Capacity | 25kg | ||

| Power | 2000W | ||

| Sensor Option | (1)Touch probe; (2)Optical probe | ||

| Motion Control | Servo control system | ||

| Software | VisionX | ||

| Input | AC200-240V, 50/60Hz | ||

| Working Environment | Temp.20℃ ±2℃ , Humidity 20~80%, Vibration<0.002g, Less than 15Hz | ||

| Note: *1 In the focus position, the environment temperature is +20 °C ± 1.0 °C, and the load on the table is 5 kg or less; L is the moving range of the table in mm. *2 It is mechanical accuracy, and actual accuracy depends on object surface where lens focuses. |

|||